Company

30 years of experience and certified quality system.

Company Profile COMIE

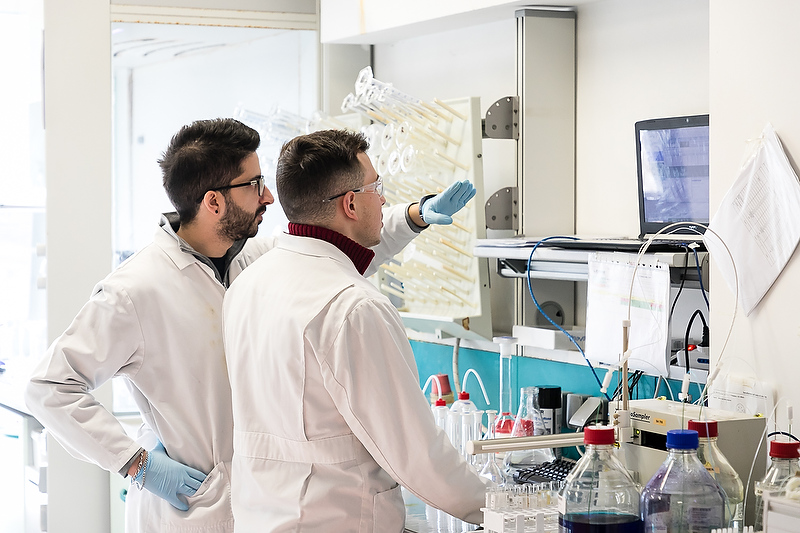

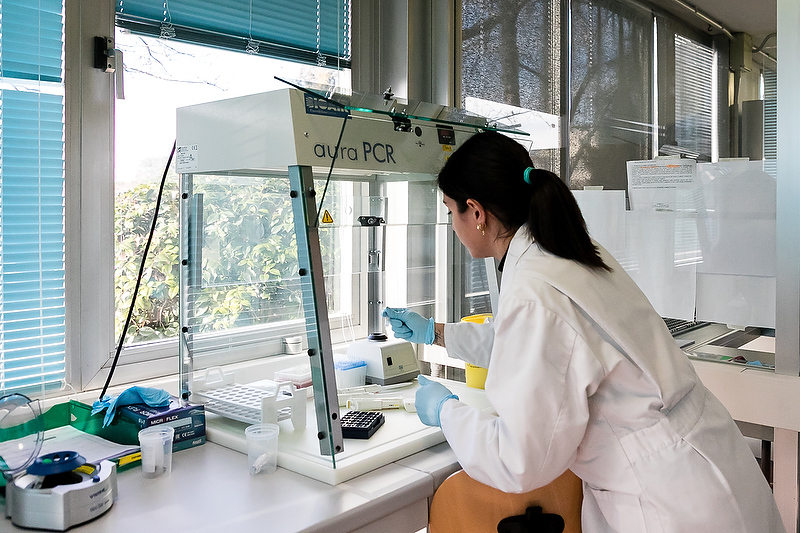

Comie chemical analysis laboratory was founded in 1992 and started its activity in the industrial context. Later on it has expanded its range of services offering food and environment analysis.

Alongside the expansion of the business area, Comie management has paid particolar attention to the improvement of the quality of the offered services in terms of sensitivity, measurement uncertainty, response time with the aim to fully meet the customers needs.

The constant increase of accredited methods following the UNI CEI EN ISO/IEC 17025 testifies to the attention Comie shows for the constant improvement of the offered services.

Comie laboratory is certified by ACCREDIA as an accredited test laboratory following the UNI CEI EN ISO/IEC 17025 and its quality, environment and safety management system is accredited following UNI EN ISO 9001, UNI EN ISO14001 and UNI ISO 45001.

The company’s mission is to provide a high-tec, reliable, unbiased, and accurate analytical service to individuals, organisations and companies. To achieve this Comie laboratory has been devoting itself to the constant improvement of tha data quality and the offered service with the aim to fully meet the customers needs and to always ensure a healthy, suitable and respectable working envirnoment as well as socially and psychologically appropriate to its staff.

More information in the document “Code of Ethics” below.

Guaranteed Results

When you go to a laboratory to request analysis regarding your products or your industrial processes you need to be certain that these analysis are performed with performance characteristics in accordance with your requirements and that the analytical results are accurate and scientifically defensible. There are many factors which may affect the accuracy of the analytical results:

- a sampling plan;

- the ongoing testing of the applied methods of the laboratory by responsible authorities;

- participation in inter-laboratory circuits;

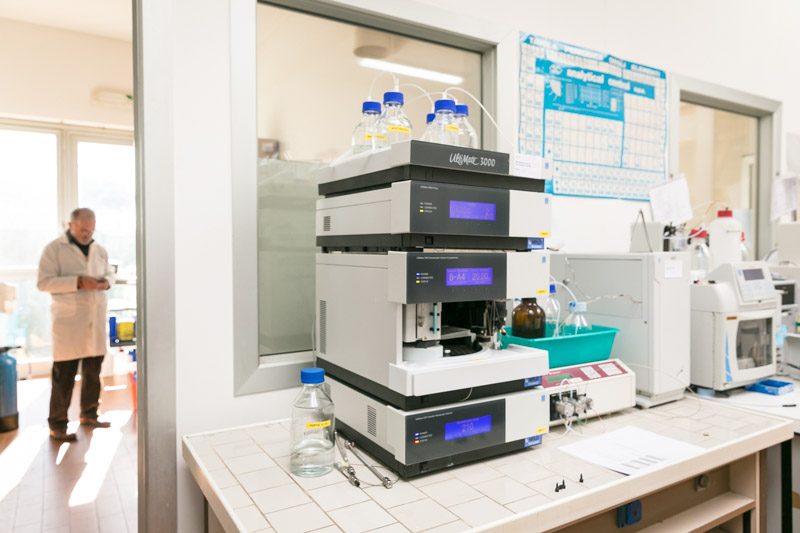

- the laboratory equipment;

- the possibility of integrating control samples in the analytical process.

The aim has always been to deliver zero error results.

To achieve this goal production indicators related to the performance characteristics of the analytical activity are constantly kept under control. Errors which would affect the data quality are dealt with by actions to mitigate and to prevent them.

The data obtained must meet the following essential specifications:

Invisible

Accuracy

THE TERM PRECISION DEFINES THE AGREEMENT BETWEEN THE RESULTS OF MORE THAN ONE MEASURE. INSTEAD, THE TERM ACCURACY DEFINES THE AGREEMENT BETWEEN THE AVERAGE VALUE OBTAINED FROM A WIDE SET OF MEASUREMENTS AND THE VALUE CONVENTIONALLY OBSERVED. RESOLUTION IS THE SIMULTANEOUS EXISTENCE OF ACCURACY AND PRECISION.

ACCURACY FOR EACH PARAMETER DEPENDS ON THE MATRIX AND THE USED METHOD.

Comie Laboratory provides analytical data issued by a set of techniques which allow to control, to mantain and to improve the quality of the offered analytical service.

Statistical techniques for analysis of results

Statistical procedures are used for each method to evaluate the obtained data in order to:

– validate test methods that are not validated before use

– check the calibration of the instruments that are not checked before use

– check the performance of the instruments that have been calibrated before use

– verify the analytical data and, where possible, verify the repeatability data

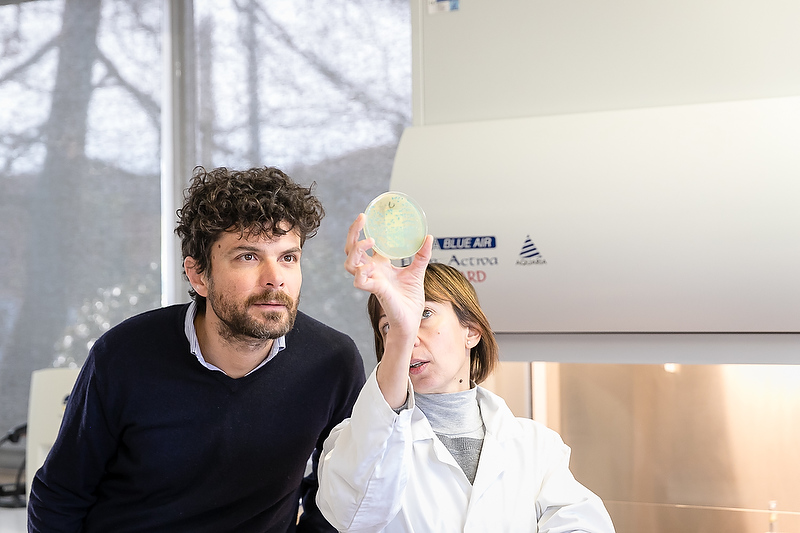

Usage of “Blind samples”

Blind samples are samples with a known concentration of analytes (e.g. distilled water with 0.5 mg/l of nichel, etc…), sent to the laboratory anonymously to simulate a sample sent by any customer without giving the staff any information. Blind samples are used for internal audit of tha staff performances and to evaluate the data quality control.

Repetition of tests

Repetitions of tests are made to check the accuracy of a test method, the performance of the instruments and their calibration. Repeatability data for a given method are generally used for:

– verify that the repeatability values declared by an official test method are respected, if available

– verify the ability to work in the stated repeatability conditions

– check the opportunity to provide a results expressed as the average of the replicated results

– verify the possibility of using a given test method with a matrix different from the delcared one

Regular use of reference materials

Certified reference materials are constantly used by Comie Laboratory to ensure the measurement metrological performances and the smooth running of the instruments.

Inter-laboratory circuits entry

Inter-laboratory tests involve the organization, the realization and the evaluation of the analytical tests made by many laboratories according to pre-determined working conditions, working on the same unknown materials.

Inter-laboratory tests are an additional element by which a test laboratory can check the quality control of a given test method.

Comie laboratory takes part periodically in national and international circuits to check and improve data reliability.

Planning of audits

Inspections are periodically carried out to examine the overall quality of the laboratory’s performance. Every aspect of the Laboratory’s activity connected with the selected tests is controlled. In particular, the following areas are considered:

– sample management

– the assigned staff

– the calibration/maintenance status of the equipment used

– the application of test methods

– recording the results and drafting test reports

– data storage

Within these areas, the following aspects are considered:

– staff’s education level and mastering of the procedures

– Historical documentation of the various procedures (e.g. measurements referability and traceability)

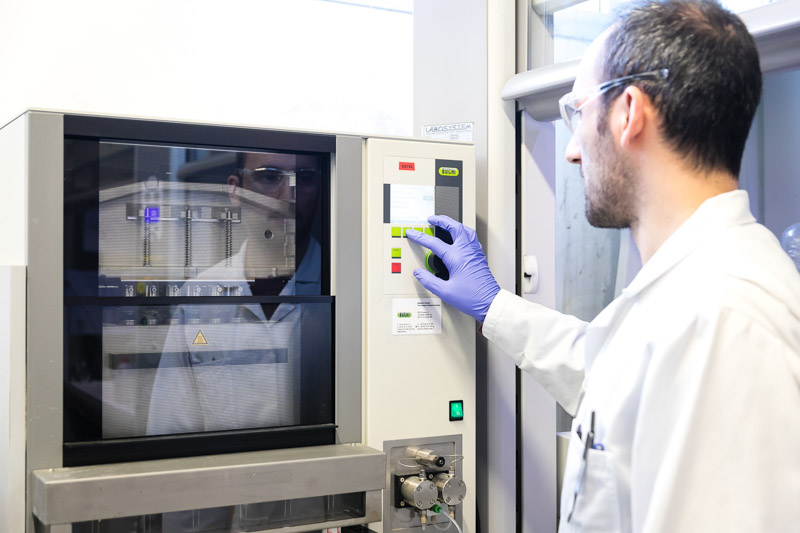

Intermediate checks

Intermediate checks are required to check the smooth running of the instruments.

Traceability

TRACEABILITY IS THE ABILITY TO TRACE THE HISTORY OF THE GIVEN DATA.

Every single step is documented, from the sampling to the analytical processes, and to avoid transcription errors all the steps are highly automated.

Data calculation and storage procedures are operated by a computer system to guarantee data traceability.

All procedures described can be verified by the customer at the laboratory.

REPRESENTATIVENESS

SATISFYING RESULTS CAN BE OBTAINED ONLY WITH A REPRESENTATIVE SAMPLE.

That’s why it is important to have a good sampling plan. It must include:

– the establishment of the target;

– the description of the sample site;

– the indication of the matrices to be sampled;

– the sampling methods;

– the length of the sampling;

– the number of samples;

– the details of the transport;

– the storage of samples;

– quality control.

By your side to guarantee the result

Contact Comie

Contact us

Phone: +39 0321 820340

Fax: +39 0321 820500

Email: info@comie.it

PEC: comie@pec.it

Address

Via Taulè, 15

SIZZANO (NO) ITALY